Keep informed by last nonwoven business news !

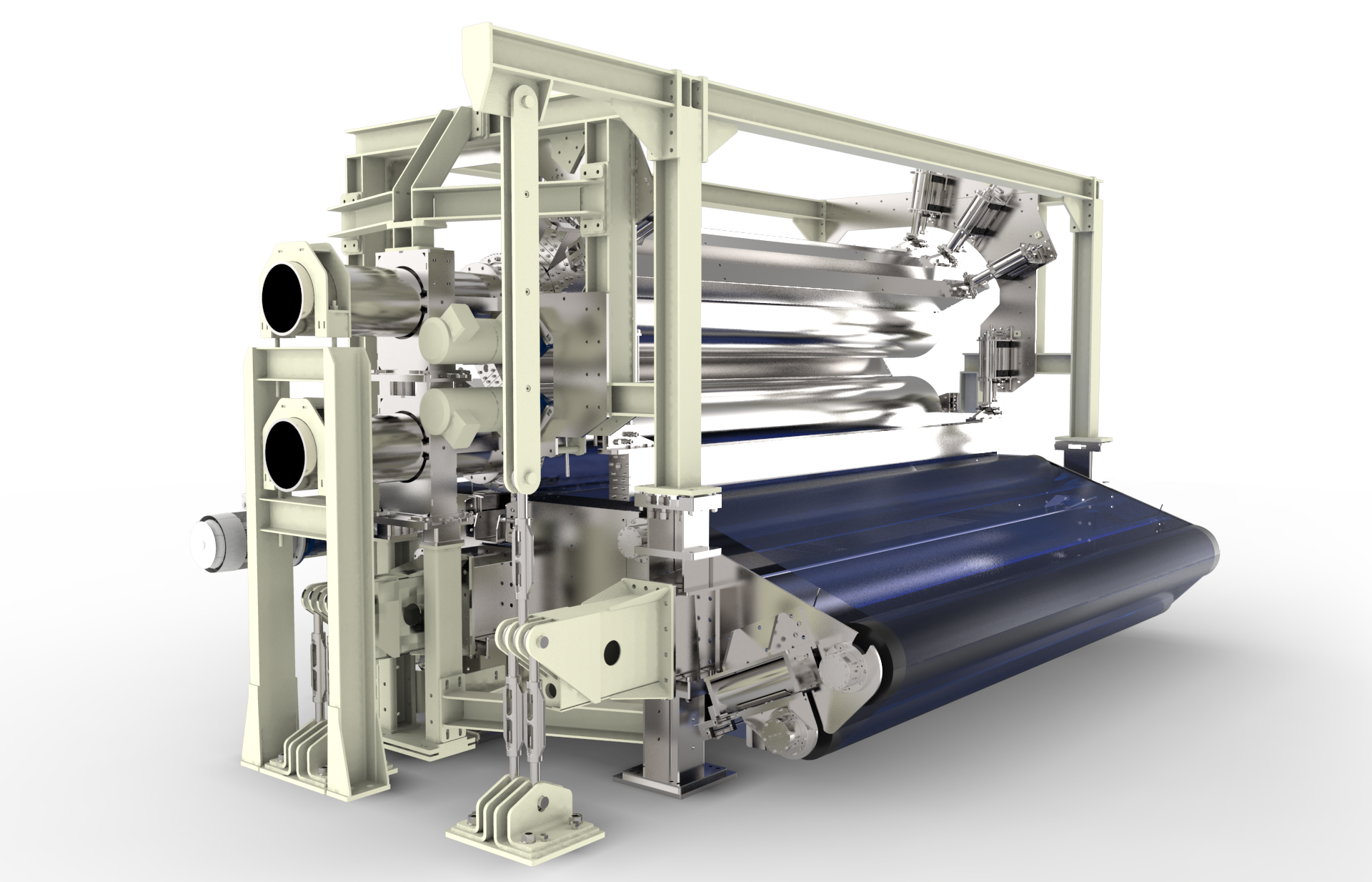

SICAM SPUNLACE Hydroentanglement Machine

SICAM will provide Complete lines for the production of Spunlace nonwovens like cotton pads, wipes and light webs laminated products.

After the forming section of the web, the water jet machine bonds the fibers on the hydroentanglement principle and a proper oven evaporate the water making the web ready for winding.

The web forming is obtained by traditional carding machine or airlay technology according to the final products.

The airlay system, suitable for low weights, the water jet, on the basis of a deep experience in Spunlace technology, the high efficiency oven and the new dewatering system make the SICAM line reference point in Spunlace production as reliability, innovation and efficiency.”

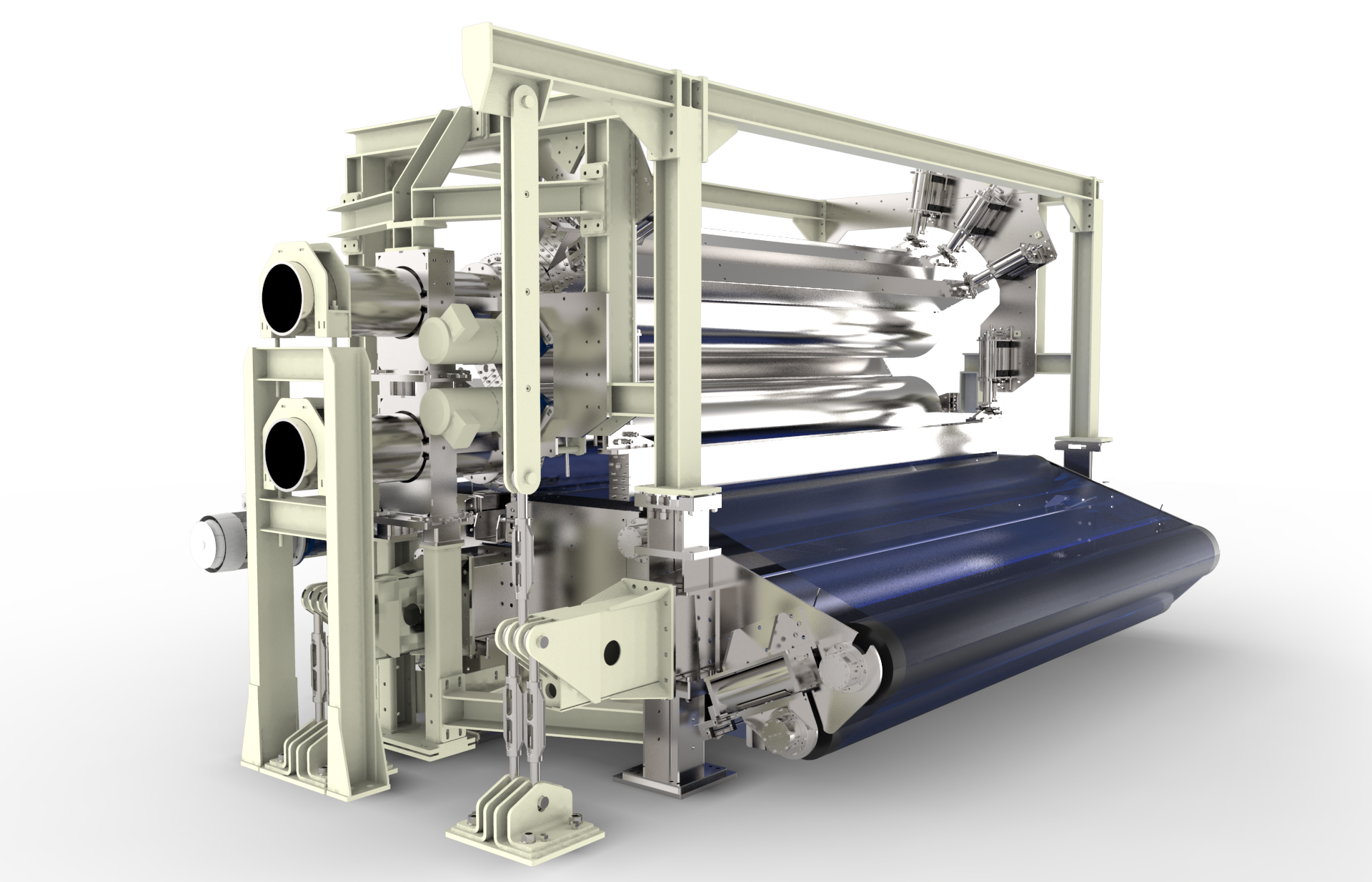

SICAM SPINNING SECTION FOR SPUNBOND ISOTROPIC INDUSTRIAL MATERIALS

SICAM SPUNBOND forming section designed by the knowledge of a team with deep experience in spun bond production lines.

As guideline the best isotropic result and high performances in strength and tenacity, SICAM spinning system can process monocomponent filaments or bicomponents filaments for a wide range of nonwovens.

Target achieved in SICAM technology are the followings:

High Isotropic resistance High mechanical properties of MD/CD

Best weight uniformity High tear resistance

High tensile strength High abrasion resistance

Best Insulation standards Optimum water repellency and transpiration”

More about all this new innovative technologies proposed by SICAM at ITMA Barcelona, Hall 5 Booth D201

1146